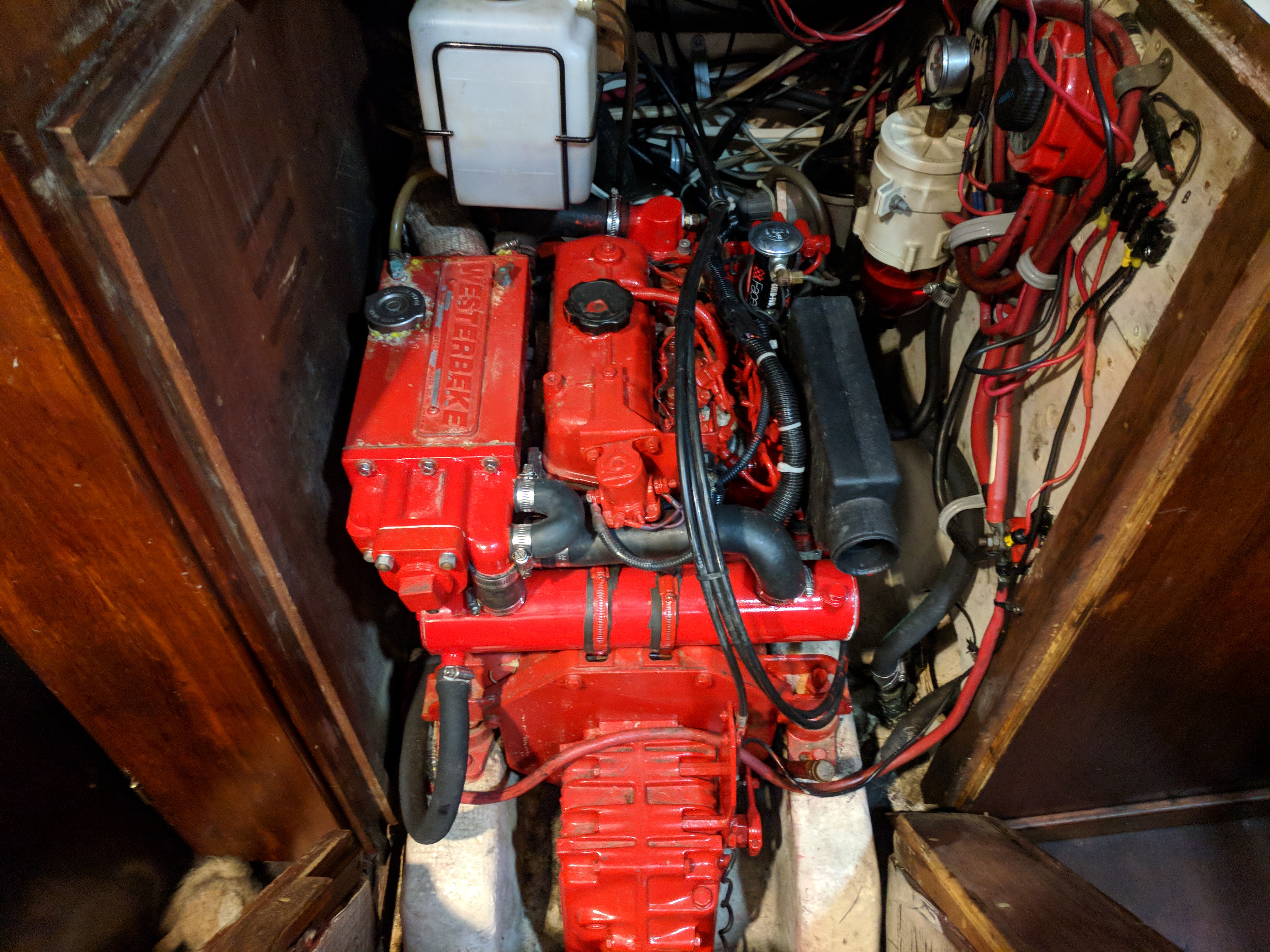

Debugging is a difficult process. As a software engineer I do it regularly so I’d like to think I’m pretty good at it. After our engine failure last week I thought that I could apply those skills to figuring out our engine troubles. After all diesel is pretty simple, all it really needs is air and fuel, right?

It wasn’t that easy. It seems that while the general process is the same, continually test while isolating causes to narrow down the possibilities, I underestimated the detailed knowledge needed to properly isolate the issue. Luckily in the months we’ve lived in the marina, we’ve made lots of friends, and many have a skill to trade.

Our friend Darby introduced us to Blake. A diesel mechanic by trade, and super nice guy. Even without meeting him, we sent him a text, and next thing we know he was on-board teaching me everything I could absorb while we chased the issue. It takes a special kind of person to put up with the number of (likely simple) questions I was continually asking, but he answered everything with enthusiasm.

We checked the simple stuff first. All the same things I had checked before, fuel lines, filter, the pump runs, etc, but since I had no idea, its better to be sure.

Once the obvious issues are dealt with, Blake really started to get into it. I love how you can tell when someone really enjoys what they do. This was a random evening, on our boat, and we had just met, but he was intrigued and he really wanted to find the problem.

We start by pulling each fuel line off to check for clogs. One by one, we pull off a line and test it. Eventually we get all the way back to the fuel tank with no clear issues. Its not a fuel line problem, so now it must be in the engine or in the fuel tank. As we discuss, I realize I don’t even know if my fuel gauge works. It has always read about 1/2 and because the boat uses so little fuel it has never moved in the 20 hours we’ve run the engine. We may just be out of fuel! We call it a day as its been about 3 hours at this point, but he is determined to find the issue so he will be back tomorrow after work and we will open the tank to check actual fuel level and the internal pickup lines.

The next day he returns with a fresh 5 gallon jerry can of diesel. That way we can isolate the fuel tank and lines as an issue. I had prepared for his arrival by opening the access hatch in the cockpit and starting the process of removing the many screws to get inside the actual fuel tank. I’m more than a little sketched out opening up a fuel tank, but he just dives right in and pops it open. Looks like my fuel gauge was accurate as it is about 1/2 full. The pickup line are good as well. So it seems the issue is in the engine itself… that sucks as that’s where parts get expensive.

Since we had all the fuel lines disconnected, we decide to try cranking the engine just with the fuel from the jerry can. It starts, but soon dies. Same problem. Next up is the internal engine fuel filter, so we pop that off and it looks surprisingly clean like it had recently been replaced. We replace it with a new one anyway and move on. We open each injector, nothing seems wrong there. High pressure return line? Seems good. At this point Blake looks genuinely stumped and I’m getting worried.

Finally, he decides just to bite the bullet and start testing the fuel pump all by itself. Its clearly running, but it seems no fuel is getting anywhere. We disconnect the line from the pump to the engine and turn it on. Nothing comes out. Aha! The fuel pump is bad! Fuel pumps are pretty resilient, and this one looks pretty new so it seems very odd that it would be bad, but we start to remove it anyway.

Suddenly he stops and says “Come look at this and tell me that I’m not crazy in what I’m seeing”. He points to the pump and I get a closer look. He specifically points to the label on the intake and outflow. Sure enough the “out” that we had just removed that went to the engine was labeled “in” and the intake from the filter was clearly labeled “out”. The damn thing was installed backwards. We swapped the intake line and turned it on. Fresh fuel starts pumping out. Unbelievable.

By this point its late again so we call it a night. We’re pretty certain the reversed pump is the issue and that the pump still works, but since its been running backward (or not at all) for who knows how long, I had better just order a new one and we will install it this weekend.

Saturday comes around, we install the new pump, and the engine starts and runs perfectly. Problem solved. I still can’t wrap my head around how the engine ran so long with the pump backwards, but Blake seems to think that due to the way the “high pressure excess fuel return line” was plumbed somehow the internal high pressure pump on the engine was able to pull fuel from the tanks return line. Totally bypassing the main pump and the filters. Once the fuel got low enough in the tank, the return line no longer was able to pull fuel and it stopped working. Still seems crazy to me, but I don’t know anything, the pump was clearly backwards, and all is running great now.

Feeling satisfied Blake is packing up to leave and I try to pay him for his time. Hes never asked, but after so many hours I feel I owe him something. After several refusals, I insist, and he says $40 would be fine. I say I would feel much better with this and hand him $100 (still severely under-payed).